How an Optical Fibre Diameter Analyser Contributes to the Development of Future Fibre Optic Systems

How an Optical Fibre Diameter Analyser Contributes to the Development of Future Fibre Optic Systems

Blog Article

Recognizing the Performance of an Optical Fibre Diameter Analyser in Modern Manufacturing

The optical Fibre Diameter analyser offers as an essential instrument in modern-day manufacturing, offering accurate, non-contact measurements that are crucial for preserving stringent market requirements. By leveraging innovative laser technology, these analysers not only make sure marginal signal loss but also improve the overall efficiency of optical fibers.

Value of Optical Fibre Dimension

In modern manufacturing, the dimension of optical Fibre Diameter is critical for guaranteeing the performance and integrity of Fibre optic systems. Precise Diameter measurement directly influences optical efficiency, as variants can lead to increased signal loss, reduced transmission capacity, and reduced general effectiveness. The optical residential properties, consisting of light transmission and signal honesty, are very sensitive to the Fibre's Diameter, requiring exact control during manufacturing.

Furthermore, standardization in Fibre Diameter is essential for compatibility and interoperability within varied telecommunications networks. As these networks broaden around the world, maintaining uniformity in Fibre attributes promotes smooth combination across various parts and systems. In addition, sticking to sector standards worrying Diameter resistances is essential for makers to fulfill regulatory demands and consumer assumptions.

Purchasing sophisticated dimension modern technologies not only boosts making performance but likewise supports quality control procedures, enabling makers to determine problems early in production. This positive approach reduces waste and makes sure that the end products meet rigorous performance standards. The significance of optical Fibre measurement can not be overstated, as it serves as a foundation for high-quality, reputable Fibre optic systems, which are essential to modern communication facilities.

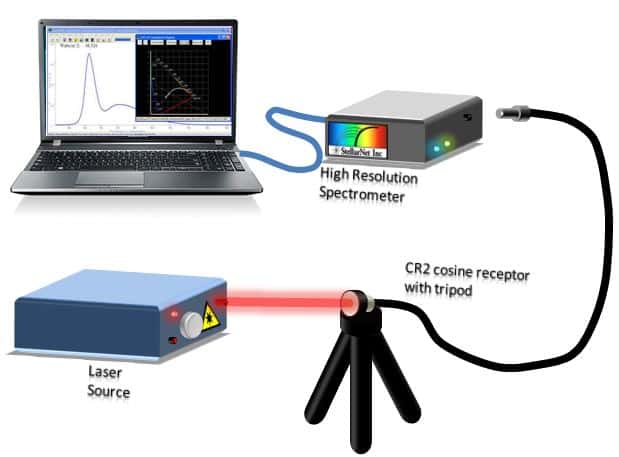

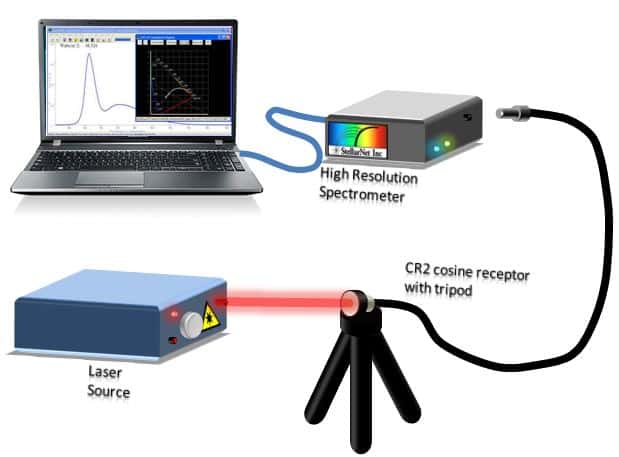

Just How Diameter Analysers Job

The core procedure counts on the principle of light scattering and representation. As the laser beam of light strikes the Fibre, variants in Diameter cause changes in the light's strength and wavelength (optical fibre diameter analyser). This information is refined in real-time making use of innovative formulas that equate the optical signals into precise Diameter measurements

In addition, lots of Diameter analysers are furnished with multiple measurement points along the Fibre, enabling a detailed analysis of Diameter uniformity. This is critical in making sure that the optical fibers fulfill stringent industry standards. The whole procedure is automated, enabling high-speed dimensions and decreasing human error. The application of such technology considerably boosts high quality control in manufacturing, making certain that optical fibres are created to precise specifications for ideal efficiency in their desired applications.

Secret Features to Take Into Consideration

When selecting an optical Fibre Diameter analyser, numerous crucial features require mindful consideration to make sure ideal efficiency and reliability. Measurement precision is extremely important; the analyser needs to give exact Diameter readings, usually in micrometers, to fulfill rigorous production specifications. In addition, a wide measurement range enhances flexibility, accommodating different Fibre types and thicknesses.

Another crucial feature is the analyser's rate. Rapid dimension abilities permit boosted throughput, necessary in high-volume manufacturing atmospheres. Real-time information processing and comments capabilities enable prompt modifications, improving quality control.

Interface and software application compatibility are also substantial factors to consider. A straightforward user interface simplifies procedure, while robust software program support promotes information analysis and assimilation with existing production systems. The ability to export information in different styles can enhance coverage and compliance initiatives.

Moreover, sturdiness and maintenance needs must be assessed. An analyser created from premium materials will certainly endure the rigours of a production atmosphere, while convenience of maintenance makes certain longevity and reduces downtime. Consider the level of technological support and training supplied by the manufacturer, as this can substantially influence the effective usage of the analyser in production settings.

Advantages in Production Efficiency

Enhancing manufacturing efficiency pivots on the integration of sophisticated innovations, such as optical Fibre Diameter analysers. These tools play a critical function in ensuring that optical fibres meet rigid quality requirements, which is crucial for optimal performance in various applications - optical fibre diameter analyser. By offering real-time measurements of Fibre Diameter, our website suppliers can promptly identify and rectify inconsistencies from specified tolerances, consequently lowering waste and decreasing the risk of faulty items

Moreover, the very early discovery of prospective problems leads to lowered downtime and maintenance prices, consequently optimizing resource appropriation. Eventually, the efficiency gets realized with making use of optical Fibre Diameter analysers add to a much more affordable manufacturing setting, making sure that firms can deliver premium products while preserving cost-effectiveness and responsiveness to market needs.

Applications Across Industries

The adaptability of optical Fibre Diameter analysers prolongs past producing effectiveness, locating applications across various sectors that rely upon optical Fibre technology. In telecommunications, these analysers are crucial for making sure the ideal efficiency of Fibre optic cables, directly affecting information transmission prices and network reliability. By precisely determining Fibre sizes, operators can reduce signal loss and enhance general interaction top quality.

The medical industry likewise benefits substantially from these gadgets, specifically in the growth of endoscopic devices and laser therapies. Accurate Diameter dimensions are vital for developing reliable optical fibers that are used in minimally intrusive treatments, improving client results with improved imaging and treatment abilities.

In aerospace, the analysers play a vital function in the manufacturing of lightweight, high-strength materials, where Fibre optics are integrated right into structural components for learn this here now monitoring and diagnostics. Additionally, the automotive industry uses these gadgets to make sure the stability of Fibre optic sensors that enhance safety and performance features in lorries.

Conclusion

In final thought, the optical Fibre Diameter analyser is important for modern production, making sure accurate dimensions that support sector requirements. The varied applications across numerous industries emphasize the analyser's importance in advertising continuous enhancement and data-driven decision-making within the manufacturing market.

In modern production, the dimension of optical Fibre Diameter is crucial for guaranteeing the efficiency and reliability of Fibre optic systems. The significance of optical Fibre measurement can not be overstated, as it serves as a structure for premium, reliable Fibre optic systems, which are indispensable to modern interaction infrastructure.

Diameter analysers use advanced optical innovations to properly determine the Diameter of optical fibres.Furthermore, lots of Diameter analysers are equipped with several measurement factors along the Fibre, allowing for a detailed analysis of Diameter official source uniformity.The flexibility of optical Fibre Diameter analysers expands past manufacturing efficiency, discovering applications across different markets that count on optical Fibre technology.

Report this page